berita terbaru

-

Raket Bola Acar Pertahanan Ikan Ganda Mendapat Persetujuan USAPA!!!

-

Bola Tenis Meja Berongga Ukiran Kerajinan Ikan Ganda: Jembatan Budaya yang Menghubungkan Tiongkok dan Dunia

-

Produk tenis meja Pisces menjadi saksi perebutan medali emas tenis meja ganda campuran pertama Wang Chuqin/Sun Yingsha di Olimpiade Paris

Kategori Produk

Panas Produk

-

Meja Tenis Meja Premium untuk Kejuaraan Raja Relevan

Meja tenis meja premium ini cocok untuk kejuaraan. Disetujui oleh ITTF dan NSCC. Silver Undercarriage + Lampu Biru

Baca selengkapnya -

Meja Tenis Meja Resmi untuk Turnamen Volant Dream 2

Meja pingpong resmi Volant Dream 2 untuk kompetisi Internasional yang dirancang oleh Double Fish Sports.

Baca selengkapnya -

Meja Tenis Meja Resmi untuk Kompetisi XIANGYU 328

Meja Tenis Meja Serbaguna Double Double Lipat, Desain kompak Sistem lipat baru meminimalkan risiko cedera selama penyimpanan meja dan bergerak. Meja tenis meja ITTF yang telah disetujui.

Baca selengkapnya -

Meja Tenis Meja Tenis Resmi untuk Tur Dunia 99-45B

ITTF menyetujui meja tenis meja tahan lama yang resmi untuk turnamen internasional. Ketebalan papan meja: 25mm KUALITAS TOURNAMENT - Meja kelas profesional ini dirancang untuk tingkat kompetisi tertinggi. SEMPURNA UNTUK KELUARGA - Menawarkan permainan premium untuk semua umur. Pergilah head-to-head atau lipat untuk latihan individual. Baja pengukur berat berukuran 2 inci mendukung tantangan terberat. Sebuah pusat besar untuk ruang permainan Anda, den, atau gym. MUDAH MAJELIS - Mulai bermain dalam hitungan menit dengan Majelis sederhana. Jaring berkualitas tinggi ini dilengkapi dengan klem pengunci yang mudah dilekatkan.

Baca selengkapnya -

Terbaik kualitas ganda ikan V40 + Volant 3 bintang meja tenis bola

Double Fish V40 + Volant 3 Stars Table Tennis Ball dikonfirmasikan ke ITTF Technical Technical T3 terbaru.

Baca selengkapnya -

Double Fish QIJI All-round Table Tennis Blade

Double Fish QIJI meja bundar tennis blade, yang merupakan meja tenis meja tenis terlaris, & nbsp; Sempurna untuk allround player tradisional.

Baca selengkapnya

Menelusuri Asal | Perkembangan Pabrik Tenis Meja Guangzhou (Bagian 2)

Sejak musim gugur tahun 1960, Pabrik Tenis Meja Chenggong menghabiskan lebih dari dua tahun untuk inovasi teknologi, yang pada dasarnya memekanisasi proses produksi utama pabrik pada akhir tahun 1963, meningkatkan keluaran dan kualitas produk, dan mulai mengekspor produk. Pada tahun 1963, produksinya mencapai 3,2 juta, lebih dari tiga kali lipat dibandingkan 780.000 pada tahun 1960, dimana 58.400 diantaranya diekspor.

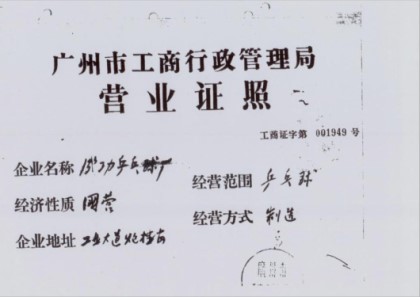

Izin Usaha Pabrik Tenis Meja Chenggong

① Isi artikel ini sebagian besar didasarkan pada data sejarah Pabrik Tenis Meja Chenggong dan 303-304 halaman Volume 5 (Bagian 1) dari "Guangzhou City Chronicles".

Namun, ketika produksi Pabrik Tenis Meja Chenggong sedang booming, kekurangan sumber daya air di kawasan Kuil Polo menjadi masalah baru yang menghambat pengembangan lebih lanjut. Pada akhirnya, departemen atasan memutuskan untuk memindahkan Pabrik Tenis Meja Chenggong ke Paolougang di sebelah Henan Industrial Avenue ② untuk mengatasi masalah kekurangan air dan memperluas skala produksi. Relokasi ini menandai dimulainya babak baru dalam perkembangan Pabrik Chenggong.

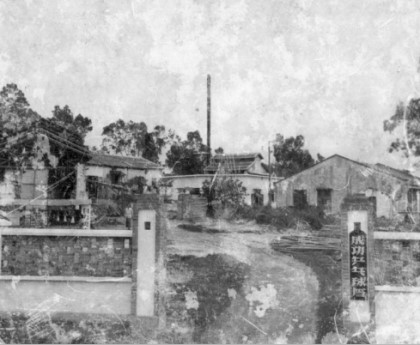

Pabrik Tenis Meja Chenggong dipindahkan ke Yanzigang, Distrik Haizhu

②Paolougang di sebelah Jalan Industri Henan sekarang menjadi kawasan Yanzigang di Distrik Haizhu. Mulai tahun 1952, pinggiran kota "Henan" di Guangzhou dibangun sebagai basis industri penting di Guangzhou. Jalan ini pernah menjadi jantung industri Guangzhou dan melahirkan banyak industri pertama di dalam negeri. Pada masa kejayaannya, Industrial Avenue sepanjang 5,5 kilometer menghasilkan produk-produk yang populer di seluruh negeri, seperti lemari es Wanbao, baterai Tiger Head, sepeda Wuyang, dll. Lahan tempat pindahnya Pabrik Tenis Meja Chenggong awalnya adalah pabrik keramik. , yang telah memiliki fasilitas dasar pabrik, sehingga memberikan kemudahan untuk perluasan produksi. Dengan dukungan kuat dari unit unggulan, Pabrik Tenis Meja Chenggong mampu membeli tanah dan memulai konstruksi, sehingga meletakkan dasar yang kokoh untuk pengembangan di masa depan.

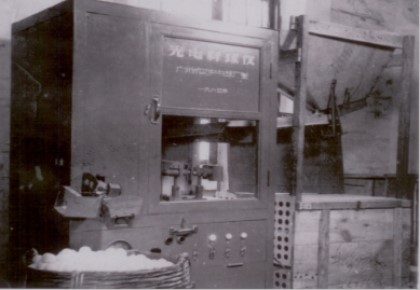

Pada tahun 1965, Pabrik Tenis Meja Chenggong kembali meraih kesuksesan dengan mengembangkan mesin timbang bola fotolistrik pertama di negara saya. Kemudian secara berturut-turut memproduksi mesin pengukur pusat gravitasi otomatis, mesin cetak merek dagang otomatis, mesin pemangkasan tepi otomatis dan mesin pengukur otomatis, dll., dan memimpin dalam mewujudkan produksi tenis meja semi-otomatis dan otomatis di industri yang sama secara nasional. Pada tahun 1966, produksi bola tenis meja melebihi 10 juta. Selama "Revolusi Kebudayaan", ia bergabung dengan beberapa pabrik dan juga memproduksi thyristor.

In 1965, Chenggong Table Tennis Factory pioneered my country's first photoelectric ball weighing instrument.

Automatic label printing machine developed by Chenggong Table Tennis Factory

In 1968, with the support and coordination of the local government, Chenggong Table Tennis Factory merged with Huada Badminton Factory③ and Zhendong Sports Goods Factory④ , significantly improving the productivity of the enterprise. Subsequently in 1969, the factory was renamed Guangzhou Sporting Goods Factory, marking the expansion of its product categories and business scope.

③According to the "Chronicles of Guangzhou City", the production of badminton in Guangzhou began in the early 1950s. With the rise of badminton, the production households continued to develop and gradually organized themselves. In 1956, the Yongjian Badminton Production Cooperative and the Yufeng Production Cooperative were formed. In 1960, the Yongjian Society was renamed the Huada Badminton Factory, with 100 employees. In 1964, the World Games brand badminton of the Yufeng Society was rated as a famous brand product in Guangzhou. During the "Cultural Revolution", all badminton production cooperatives were merged into the Chenggong Table Tennis Factory.

④Zhendong Sports Goods Factory mainly produced wooden-handled skipping ropes, table tennis nets, and volleyball nets. Before the merger, the two factories were located on the streets in the urban area, with scattered and narrow factory buildings (all old residential buildings), making material transportation and management extremely inconvenient. The merger improved the production conditions of such products. This article is compiled based on the oral narration of the retired leaders of Guangzhou Table Tennis Factory.

In 1972, the company was renamed Guangzhou Table Tennis Factory. In the same year, Guangzhou Table Tennis Factory introduced the innovative wax expansion method, replacing the old steaming process for producing close-seam balls, which doubled the work efficiency. The introduction of this technology not only improved production efficiency, but also made Guangzhou Table Tennis Factory the first company in China to achieve full mechanization of close-seam ball production.

Table tennis ball expander from the mid-1970s

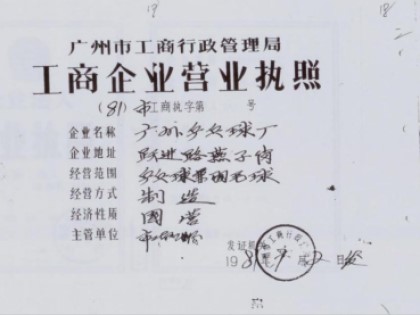

Guangzhou Table Tennis Factory Business License

In 1974, after five months of unremitting efforts and more than 130 precision tests, the Guangzhou Table Tennis Factory successfully developed China's first hard table tennis ball. This achievement marked a major breakthrough in China's table tennis manufacturing technology. The product was subsequently named "Shuangyu Brand". In 1979, this table tennis ball was officially approved by the International Table Tennis Federation and became the designated ball for international official competitions.

In 1980, "Double Fish" brand table tennis balls were officially rated as a national famous trademark and won the National Gold Award in the same year.

Doublefish table tennis won the national gold medal certificate

In 1981, with the booming domestic and foreign markets for badminton, the Guangzhou Table Tennis Factory restarted the production of badminton with the formal approval of the competent authorities. It focused on creating special balls for high- and mid-end competitions, strictly selected high-quality white goose feathers, and used imported cork and artificial leather as ball head materials to produce badminton with excellent whiteness, strong flight stability, and precise landing points. All products were sold to the Japanese market.

From 1986 to 1990, the annual output of badminton achieved an average high growth rate of 31%. In 1989, advanced Japanese production equipment was introduced, which greatly improved the production capacity and reached an annual production capacity of 24 million. In 1987, the Jinque brand badminton in the domestic market was rated as a high-quality product by the Ministry of Light Industry, and in 1990 it won the official certification of the national competition ball, marking the full recognition of product quality and technical level.

In 1986, as sales continued to expand, Guangzhou Table Tennis Factory set up branch factories in Zengcheng and Huaxian (now Huadu District, Guangzhou), focusing on producing mass-market table tennis balls to meet domestic market demand, while the main factory was committed to producing mid- and high-end table tennis balls for export. In 1987, total production soared to 63.02 million, of which 54.82 million were sold to overseas markets, generating US$2.18 million in foreign exchange revenue.

In 1988, the outstanding performance of Guangzhou Table Tennis Factory won the honorary titles of Provincial Advanced Enterprise and National Second-Class Enterprise. In 1990, Guangzhou Table Tennis Factory invested 2.5 million yuan in factory construction and technical transformation to further improve production capacity. In November of the same year, a new celluloid sheet plant was established in Zengcheng with an investment of nearly 2.57 million yuan. Through this series of transformation and expansion, the annual production capacity of table tennis balls doubled from 60 million to 120 million, making Guangzhou Table Tennis Factory one of the important bases for table tennis ball production in the world.

Guangzhou Table Tennis Factory in the 1990s

In 1994, the company relocated and expanded again⑤, requisitioned 50 mu of production land in Dabu Management District, Mayong Town, Dongguan City, relocated and renovated it, expanded its production scale, and achieved rapid improvement in production quality, laying a solid foundation for the company's sustainable development.

⑤ Karena komponen utama seluloid, bahan baku produksi tenis meja, adalah nitroselulosa, bahan ini sangat mudah terbakar dan telah menyebabkan banyak kecelakaan kebakaran serius di Tiongkok, termasuk kecelakaan kebakaran di Pabrik Tenis Meja Double Happiness di Shanghai dan Tianjin Pabrik Tenis Meja. Pada tanggal 14 Oktober 1993, Pabrik Tenis Meja Guangzhou juga mengalami kebakaran yang mengakibatkan bangunan seluas 4.000 meter persegi terbakar. Selain itu, pesatnya pertumbuhan kawasan pemukiman di dekat Yanzigang pada tahun 1990-an membuat bahaya keselamatan di kawasan tersebut semakin menonjol. Mengingat hal ini, Pabrik Tenis Meja Guangzhou memutuskan untuk merelokasi seluruh lini produksinya dan memindahkannya ke Dongguan untuk memastikan standar keselamatan dan efisiensi produksi yang lebih tinggi.

Pabrik Dongguan pada tahun 1990-an

Pada tahun 1995, berdasarkan pengaruh signifikan merek "Doublefish" , Pabrik Tenis Meja Guangzhou secara resmi berganti nama menjadi Pabrik Barang Olahraga Guangzhou Doublefish.

Pada tanggal 26 Februari 1998, Pabrik Alat Olah Raga Guangzhou Shuangyu digabung menjadi Guangzhou Shuangyu Sporting Goods Group Co., Ltd.

+8620-84319554

+8620-84319554 +8620-84328948

+8620-84328948

+86 13829778212

+86 13829778212